In the world of construction, precision is the name of the game, and laser screeds have become an indispensable tool in achieving perfectly level and smooth concrete surfaces. These innovative machines offer a remarkable blend of accuracy and efficiency, making them a must-have for a wide range of construction projects. However, selecting the most suitable laser screed model is not a one-size-fits-all endeavor. It requires a comprehensive understanding of your project’s specific needs, considering factors like size, scope, and requirements. In this guide, we’ll walk you through the essential steps to help you make the right choice.

1. Define Your Project Size and Scope

The first and most crucial step in choosing the right laser screed is to assess the size and scope of your construction project. Laser screeds come in various sizes and configurations, and selecting the appropriate one will significantly impact the success of your endeavor. Consider the following questions:

- Is your project relatively small, such as a residential driveway, sidewalk, or patio?

- Do you have a mid-sized project, like a warehouse floor, a parking lot, or a retail space?

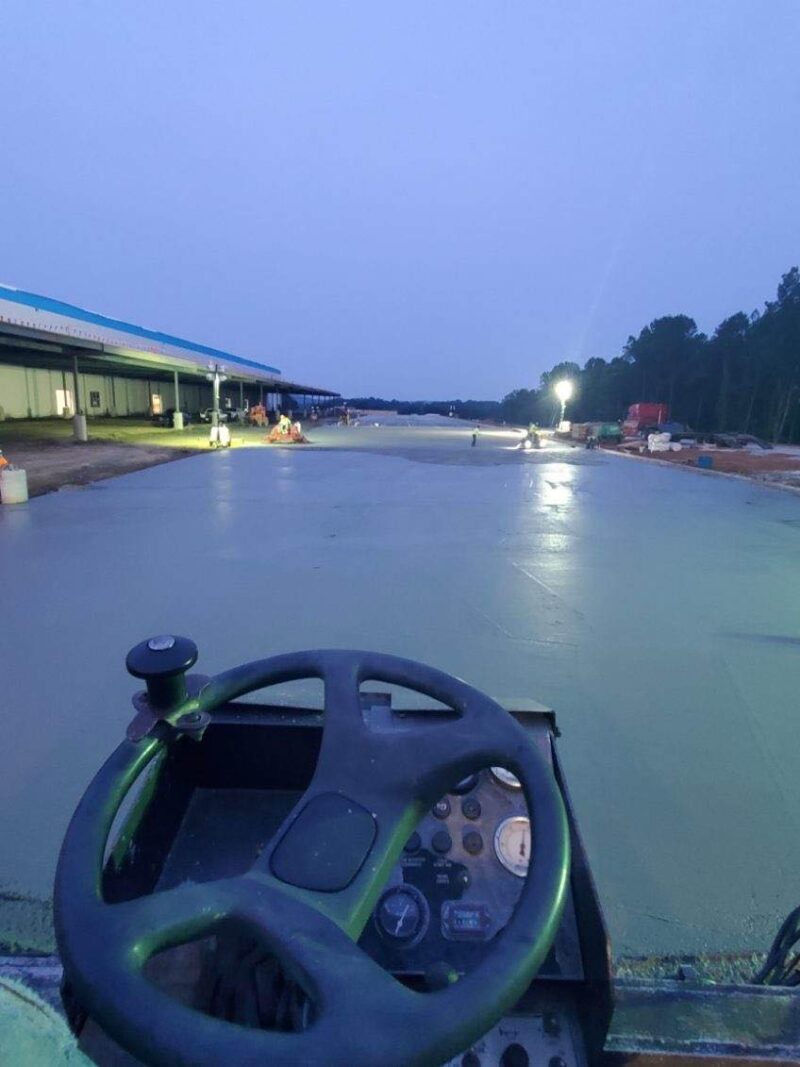

- Are you tackling a large-scale construction project, such as highways, runways, or expansive industrial buildings?

The size and scale of your project will serve as a pivotal guide for narrowing down your laser screed options.

2. Evaluate Your Budget

Budget considerations are paramount in any construction project. Laser screeds vary in cost based on their features, capabilities, and technology. Determine your budget range and be prepared to invest in a machine that aligns with your requirements. While staying within your budget is crucial, remember that a slightly higher upfront cost can often lead to long-term savings and superior efficiency.

3. Assess the Necessary Features

Different laser screeds come equipped with a variety of features and capabilities. To make an informed decision, assess your project’s specific needs and identify the features that are critical to your success. Here are some key features to consider:

- Laser System: Choose between 2D or 3D laser systems, depending on the complexity of your project. A 2D system may suffice for straightforward flatness, while a 3D system is essential for projects that require slope and elevation control.

- Screed Head Size: The size of the screed head dictates the width of the concrete pass. Smaller heads are suitable for narrow spaces, while larger ones are ideal for expansive areas.

- Machine Mobility: Consider whether your project requires a ride-on or walk-behind laser screed, based on the terrain and accessibility of the work site.

- Concrete Type and Mix: Your choice of laser screed should accommodate the type and consistency of the concrete mix you’ll be using. Be sure it’s compatible with your project’s specific requirements.

4. Factor in Long-term Maintenance and Support

It’s crucial to account for the long-term maintenance and support of your chosen laser screed. Investigate the manufacturer’s reputation for durability, the availability of replacement parts, and the quality of customer support and service.

5. Seek Expert Guidance

Choosing the right laser screed can be a complex task, and seeking guidance from experts in the field is often a wise move. Don’t hesitate to consult with experienced professionals who can provide insights based on your project’s unique needs.

Conclusion

Selecting the right laser screed for your construction project is a decision that should not be taken lightly. By defining the project’s size, assessing your budget, evaluating necessary features, and considering long-term maintenance and support, you can make an informed choice that ensures precision and efficiency throughout the project’s duration. Your laser screed is more than just a tool; it’s a critical investment in the success of your construction venture.